DIODE CONTROLLED ANODES

Diode Controlled Cathodic Protection

The diode-controlled cathodic protection system has been developed to

prevent hydrogen embrittlement to high-strength stainless steels that

require cathodic protection.

Typical applications for the product are 13% Cr, 22% Cr duplex and 25%

Cr duplex pipelines, however, the system is also suitable for application

to high-strength carbon steel materials where low potentials from the

CP system may be a problem.

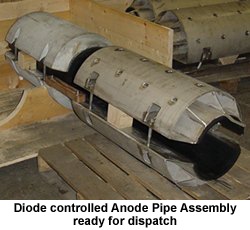

The system is installed as a part of the anode and no maintenance is

required during the operational phase.

Compared to a traditional design according to the NORSOK M-503 or the

DNV-RP-B401 standards, the Diode-controlled Cathodic Protection system

design will reduce the anode amount significantly.

Applications

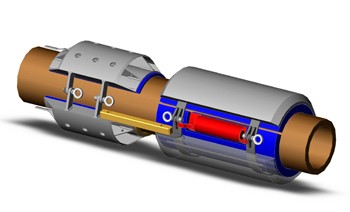

The system is based on a diode installed with the anode and the cathode.

The diode shall ensure a sufficient potential drop between the anode

and the cathode to avoid any risk for hydrogen embrittlement of the

pipe material. It shall also be ensured that the potential is sufficiently

low to avoid corrosion on the material.

The diode package is a completely sealed unit that is designed for a

maximum hydrostatic pressure of 260 bar. The materials in the unit have

been selected to withstand corrosion at high seawater temperatures even

without cathodic protection. For the design of the system, pipeline attenuation

calculations combined with sensitivity considerations is applied together

with traditional cathodic protection calculations.

The diode package is a completely sealed unit that is designed for a

maximum hydrostatic pressure of 260 bar. The materials in the unit have

been selected to withstand corrosion at high seawater temperatures even

without cathodic protection. For the design of the system, pipeline attenuation

calculations combined with sensitivity considerations is applied together

with traditional cathodic protection calculations.

During

the development of the system, extensive testing has been performed to

find realistic current density data for buried pipelines operating at high

temperatures. The results from this testing are applied in the design of

the system to ensure an operating condition in accordance with the design

calculation. The Diodes are very reliable and have been through a rigorous

testing programme so, unlike traditional diode systems which have reputation

for failure during the early parts of service, these diodes have a probability

of failure exceeding 1 in 20 million chance.

The final product assembly is suitable for any situation in which lower controlled

levels of potential are required. The configuration can be adjusted to suit pipeline

bracelets or supplied with a shaped baseplate for flush fit for hulls or frames.

Pipeline Bracelet Assembly |

Flush Fit Assembly |

|

|

This system's main points:

- Runs on hot pipes up to 150 centigrade (utilising rubber inserts under the anode materials to work where others may not)

- Controls potentials accurately and reliably

- Set to any controlled potential you like by design

- Prevent cracking in susceptible areas such as weldments in high strength steel & at joints and anode pads

- Easily installed using conventional tooling

- Reduces amount of installation points

- Saves on installation contractor time

- Proven track record on 5 project successfully to date.

- Is very reliable

- Can be configured for use on pipelines, vessels, frames and submersibles

23 - 41 Willowdale Place, Aberdeen, AB24 5AQ, Scotland

Tel: +44 (0)1569 768088 - Fax: +44 (0)1224 624377 - e-mail: sales@aberdeenfoundries.co.uk